Against the backdrop of the accelerating transformation of the global automotive industry towards electrification and intelligence, Carbon Fiber Reinforced Polymer (CFRP) is becoming a core strategic material for high-end automotive manufacturers and new energy vehicle companies due to its excellent strength to weight ratio and disruptive innovation potential. As a deep cultivation of global supply.

二、Why has carbon fiber become the “golden material” for automobile manufacturing?

- Lightweight Revolution

The density of carbon fiber is only 1/5 of steel and 2/3 of aluminum, yet it can achieve 5 times the tensile strength of steel. For every 10% reduction in vehicle weight, fuel vehicles can reduce energy consumption by 6-8%, while electric vehicles can extend their range by 5-15% (data source: SAE International)。

- Dual upgrade of security and performance

-Collision energy absorption efficiency increased by 300% compared to traditional materials

-Anti fatigue characteristics extend the service life of key components

-Low thermal expansion coefficient ensures dimensional stability at extreme temperatures

- New standards for sustainable manufacturing

Through thermoplastic carbon fiber recycling technology, industry-leading enterprises have achieved a 95% material recycling rate, perfectly aligning with the EU ELV directive and global carbon neutrality goals.

二、Six innovative application scenarios of carbon fiber in the automotive field

1. Body in White structural components

Integrated frame reduces weight by over 40%

Modular design reduces assembly costs by 20%

2. Specialized solutions for new energy vehicles

Battery pack shell: flame retardant V0 certification+electromagnetic shielding design

Hydrogen fuel storage tank: 70MPa high pressure tolerance

Motor rotor: reduce inertia loss and improve torque response

3. High performance subsystems

Brake disc: 60% lighter than cast iron parts, with a temperature resistance of up to 1000 ℃

Drive shaft: critical speed increased by 200%, eliminating resonance risk

Suspension arm: Optimization of unsprung mass improves handling accuracy

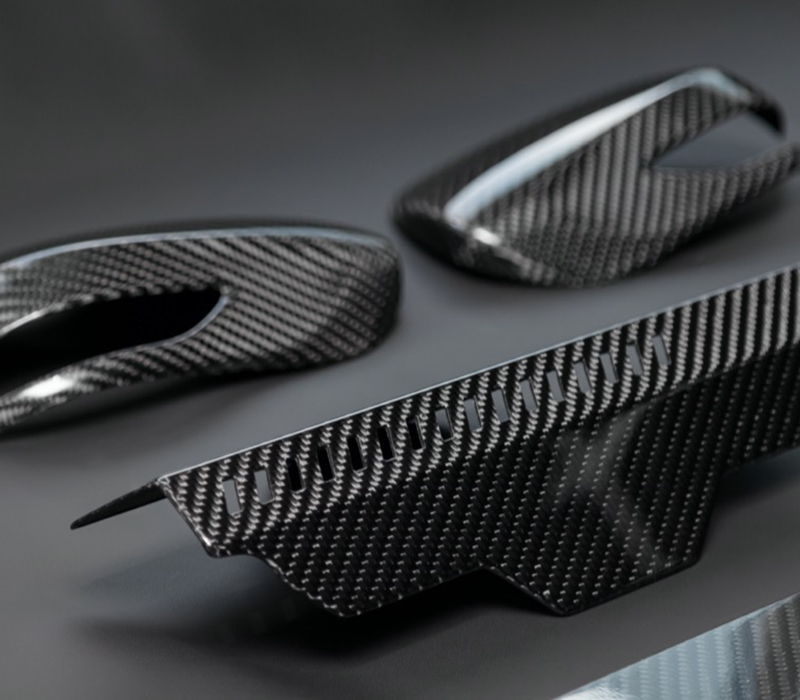

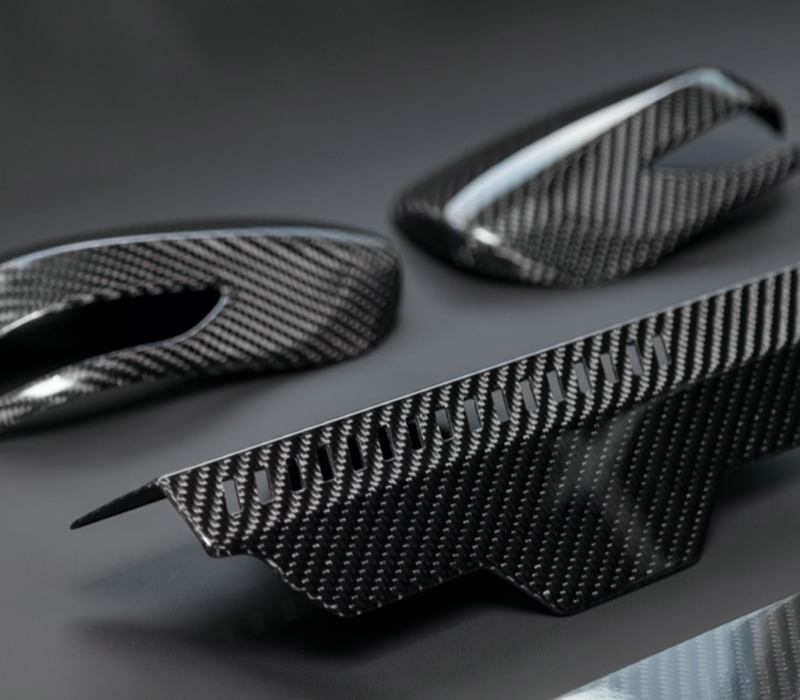

4. Interior and exterior customization

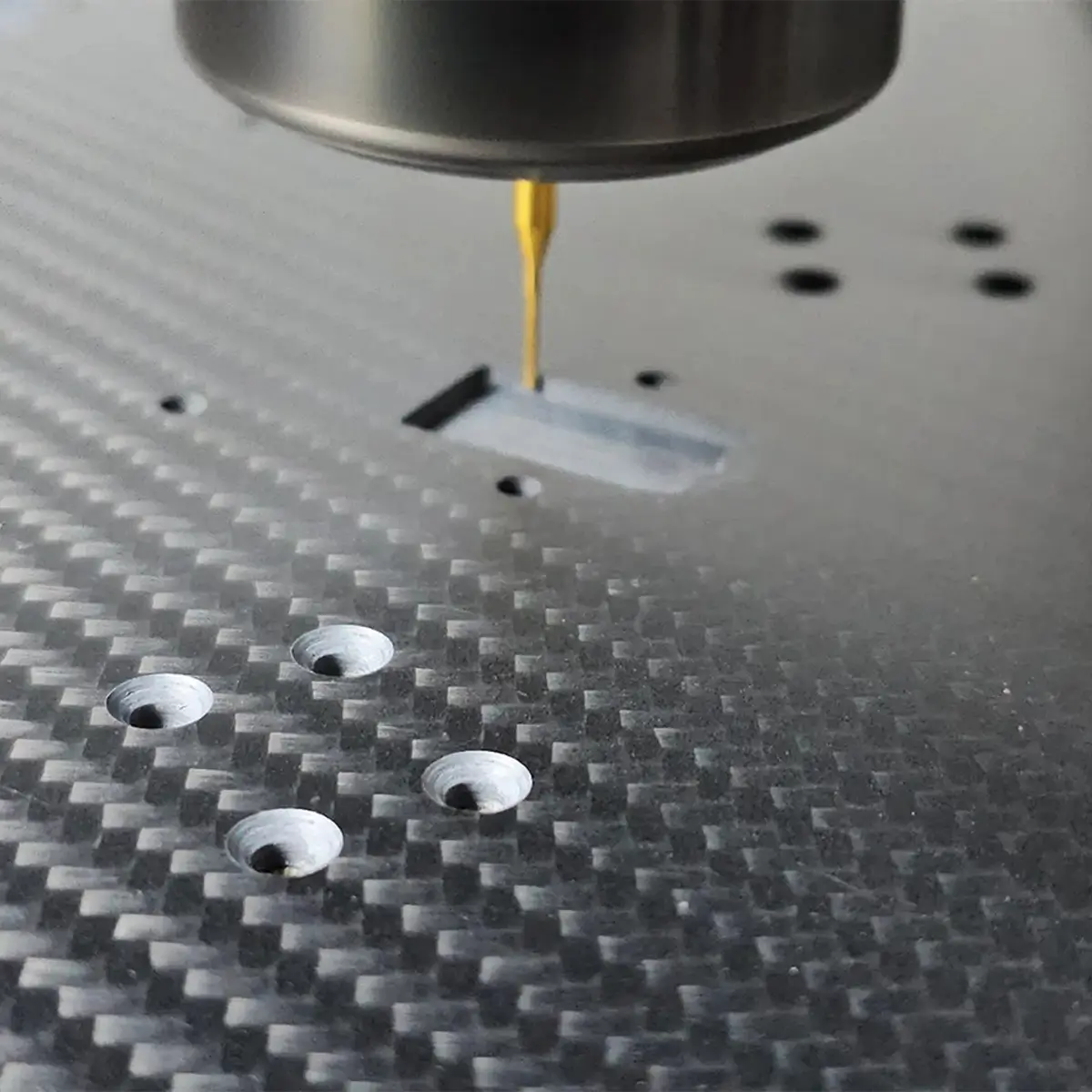

3D weaving technology achieves complex surface modeling

Class A surface treatment meets the glossiness requirements of luxury cars

Natural matte texture creates high-end brand recognition

if you have any need for custom carbon fiber parts , Pls feel free to contact us to get the quotation ! Thank you very much