LJ Carbon Fiber Factory

CNC Surface finishing services

Get reliable cnc surface finishing services for your plastic and metal parts, made and delivered when you need them.

Our team is here to help take your product from design and prototyping all the way to full production.

From single prototypes to large-scale production runs of up to 10,000 units, we adapt to your project’s requirements. Parts are ready in as little as 3 days.

Our state-of-the-art in-house machine shop is powered by a team of over 100 experienced professionals dedicated to delivering excellence.

We achieve tight tolerances of ±0.010mm, ensuring your components meet even the most stringent specifications.

As an ISO 9001:2015 certified manufacturer, we guarantee high-quality products and consistent performance every time.

CNC Chemical Finishes

Chemical finishes play a crucial role in improving a part’s durability, thermal stability, conductivity, and lifespan.

| Type | Material Compatibility | Colour | Description |

|---|---|---|---|

| Anodizing | aluminium, titanium | gold, red, blue, black, clear, etc. | Provides increased surface hardness, wear resistance, and enhances the lifespan of aluminium components. |

| Electroplating | Metals & plastics | Metallic | Perfect for maintenance and decoration, with options to coat parts in chrome, zinc, or nickel, offering a polished finish. |

|

Electrophoresis Blackening |

Steel, copper, aluminium, etc. | Heavy black | Adds a protective layer to reduce corrosion and minimize surface reflection for an improved aesthetic and durability. |

| Passivation | Stainless steel | Very light blue | Enhances the corrosion resistance of stainless steel components, making them ideal for demanding applications. |

| Alodine | Aluminium | Clear, yellow | A chromate conversion coating that boosts corrosion resistance while maintaining electrical conductivity. |

CNC Mechanical Finishes

Mechanical finishing plays a vital role in creating distinct surface textures on metal and plastic components.

| Type | Material Compatibility | Colour | Description |

|---|---|---|---|

| Bead Blasting | Metals & plastics | Raw material colour | Achieves a consistent matte or satin finish using glass beads, ideal for eliminating tool marks and surface contaminants. |

| Sandblasting | Metals & plastics | Raw material colour | Delivers a uniform matte surface and is often used for aesthetic purposes, offering a range of grits for varied textures. |

| Brushing | Metals | N/A | Produces a sleek, unidirectional satin texture by systematically polishing the metal with fine grit. |

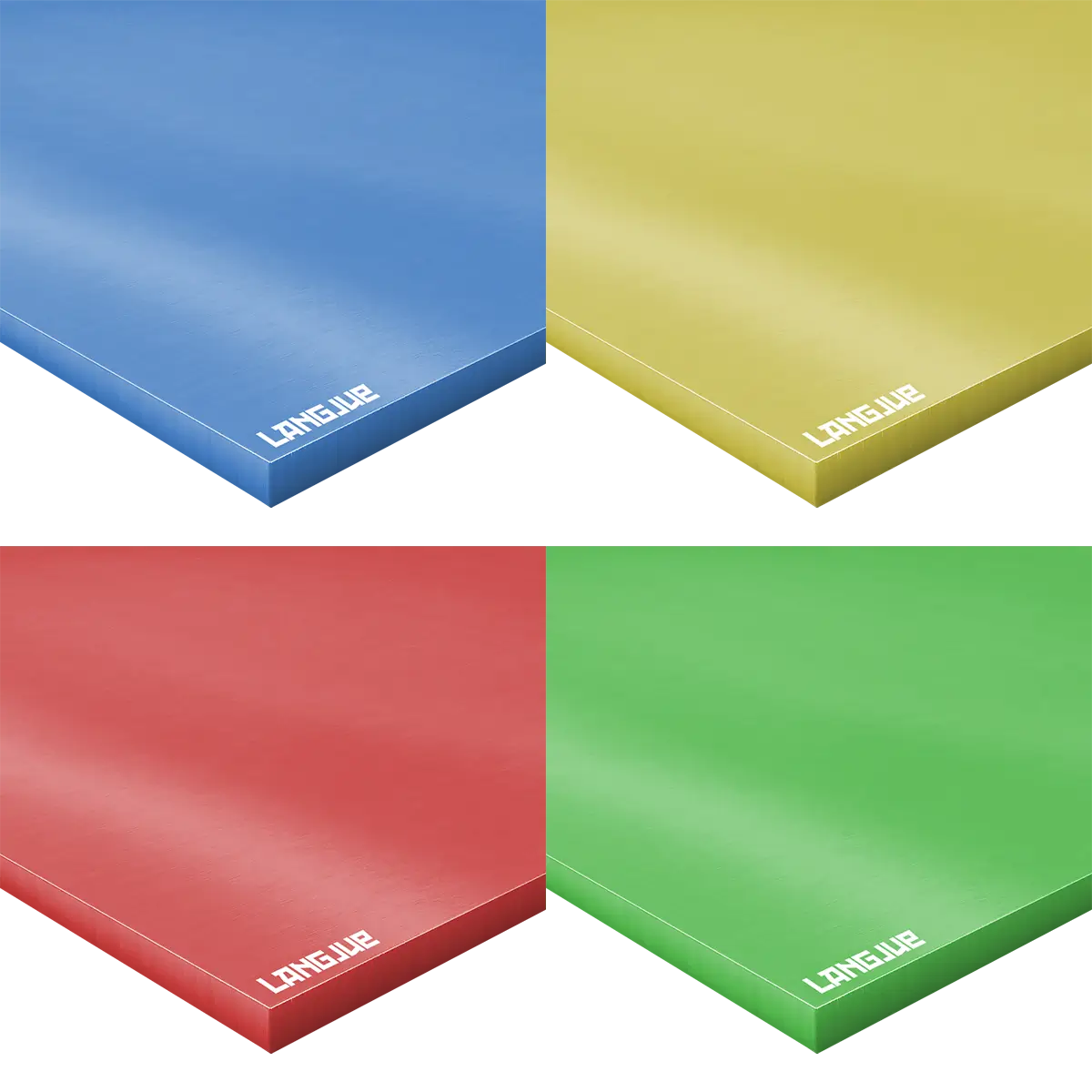

| Painting | Metals & plastics | Black, RAL/Pantone colours | A reliable way to add vibrant colors and improve the overall visual appeal of CNC-machined parts. |

| Powder Coating | Metals | Black, RAL/Pantone colours | A robust, dry finishing technique that provides a hard, smooth surface, surpassing the durability of traditional paint. |

| Polishing | Metals & plastics (especially PMMA) | N/A | Hand polishing enhances CNC components with a glossy, reflective finish, creating a premium appearance. |

CNC Surface Treatment SHOW

Choose CNC Surface Finishes

Expert surface treatment techniques for optimal aesthetics and functionality

Upload Your CAD File

To begin, provide your contact details and upload the CAD file of your design. This allows us to create a detailed 3D model of the part or prototype you're looking to produce.

Receive a Quote & Design Review

Within 12 hours, we’ll send you a detailed quote along with Design for Manufacturability (DFM) feedback. This ensures the feasibility of your project and gives you a clear idea of the costs involved.

Confirm Your Order & Begin Production

Once you approve the quote and design, we’ll proceed with the production of your CNC prototype or machined parts.

Shipping & Delivery

Your CNC machined parts will be completed within a few days and shipped via international express. We encourage you to share feedback to ensure your order meets your expectations.

Just 4 Steps

The CNC Surface Finishing Quotation

From detailed consultation to final delivery, we make custom parts orders simple and easy. We pride ourselves on providing exceptional customer service by anticipating your needs, offering customized solutions and on-time delivery.

To offer an accurate and detailed quote, we require the following details:

1.CAD files in 2D or 3D formats, including STP, IGES, X_T, DWG, PDF, or STL.

2.The desired quantities, machining processes, and the type of raw materials.

3.Any secondary operations required, such as finishing, heat treatments, anodizing, or plating.

4.Specific customer requirements, including First Article Inspection (FAI), PPAP, or external certification needs.

5.Additional helpful information, like target pricing or expected lead times.

As a contract manufacturer, we don’t typically handle part design, but we can assist with Design for Manufacturability (DFM). Through DFM guidance, we help optimize your design for efficiency and cost reduction while maintaining its intended functionality.

We strive to respond to quote requests within one business day. To expedite the process, please provide complete and accurate project information, which helps us deliver faster and more precise feedback.

Our lead times vary depending on our current workload, the part’s complexity, and the order size. After your purchase order is confirmed, documentation completed, and materials secured, we’ll provide an exact delivery timeframe. This can range from as little as three business days to several weeks.

For international orders, quality assurance is key, and our ISO-9001-certified facility ensures consistent, reliable results. Equipped with advanced inspection tools and a skilled QC/QA team, we deliver:

1.2D inspection reports, CMM reports, or 3D scanning reports.

2.Full documentation of all dimensional tolerances, geometric tolerances, and specifications.

3.Statistical sampling based on MIL-STD-105E standards, guaranteeing zero defects.

All inspection reports are packaged and sent along with your completed parts for transparency and peace of mind.

CNC Surface Finishing FAQs

We provide precision parts made from engineering-grade materials, perfect for functional tests or final use. Explore our FAQs to learn more about CNC machining services and related technical support.

CNC Surface Finishing FAQs

We provide precision parts made from engineering-grade materials, perfect for functional tests or final use. Explore our FAQs to learn more about CNC machining services and related technical support.

CNC machining, or computer numerical control machining, encompasses a variety of processes we specialize in, such as: Precision milling, Turning, Drilling, Threading and tapping, EDM and wire EDM, Custom surface finishing, Prototype manufacturing, Small-batch and one-off runs, Modifying existing parts, Assistance with material sourcing, Limited warehousing and organized part dispatching, We handle projects from prototypes to full-scale production, delivering anywhere from 1 to 10,000 pieces. Quick turnarounds are a priority, with deliveries available in as few as three days.

Our dedicated engineering and sales teams provide tailored quotes based on your project needs. For similar components, CNC lathe machining typically costs 15% less than standard 3-axis milling. However, continuous 5-axis milling is approximately 20% more expensive than indexed 5-axis (or 3+2 milling) and can cost twice as much as 3-axis milling. For cost efficiency, consider larger production runs to offset setup expenses.

3-Axis Milling: Maximum dimensions of 1270×508×635 mm

5-Axis Milling: Maximum dimensions of 450×700×400 mm, with a worktable diameter of Φ400 mm

The standard finish, known as “as-machined” or “as-milled,” displays minimal tool marks. Surface roughness (Ra) typically falls between 1.6-3.2 μm. Enhanced finishes, ranging from 0.8-1.6 μm to 0.2-0.8 μm, are available for projects requiring a finer texture, though additional costs and machining time may apply.