LJ Custom Carbon Fiber Factory

LangJue Custom Carbon Fiber Parts

For You According To Drawings

We specialize in tailoring custom carbon fiber parts to the unique and rigorous demands of diverse customers and applications, from consumer goods to medical devices to robotics to car. Review your customization options below and let’s bring your vision to life.

Consistent Processes

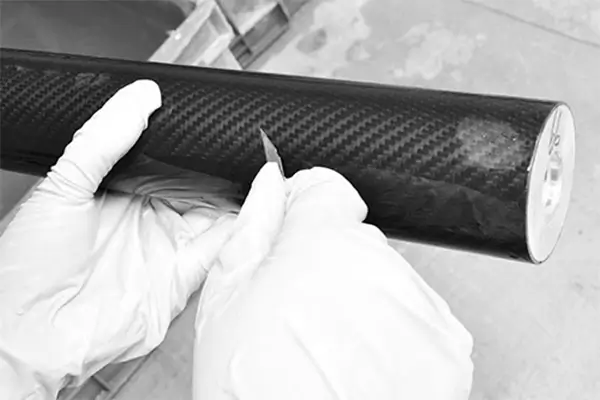

Our ISO 9001 certified manufacturing process is rigorously controlled to ensure perfection on every job, every time—guaranteeing zero porosity, no cosmetic defects, and 100% satisfaction.

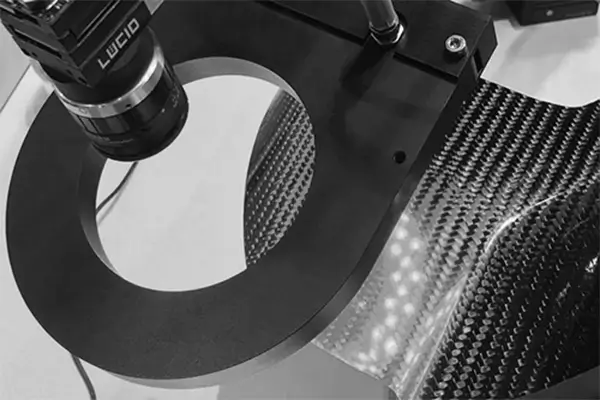

Rigorous Quality Control

Each product undergoes an extensive quality inspection before shipment, ensuring flawless, high-performance custom carbon fiber parts that meet the highest standards.

Advanced Customization

We specialize in turning your precise designs and performance requirements into reality, even for the most complex and challenging projects.

Timely Delivery

We prioritize efficiency and reliability in our production timeline, ensuring that your custom carbon fiber parts are delivered on time, every time, without compromising on quality.

custom carbon fiber Material

Choose weave and filament count

Select custom carbon fiber parts weave pattern and filament count for optimal strength and performance, with full customization options to meet any specification or requirement

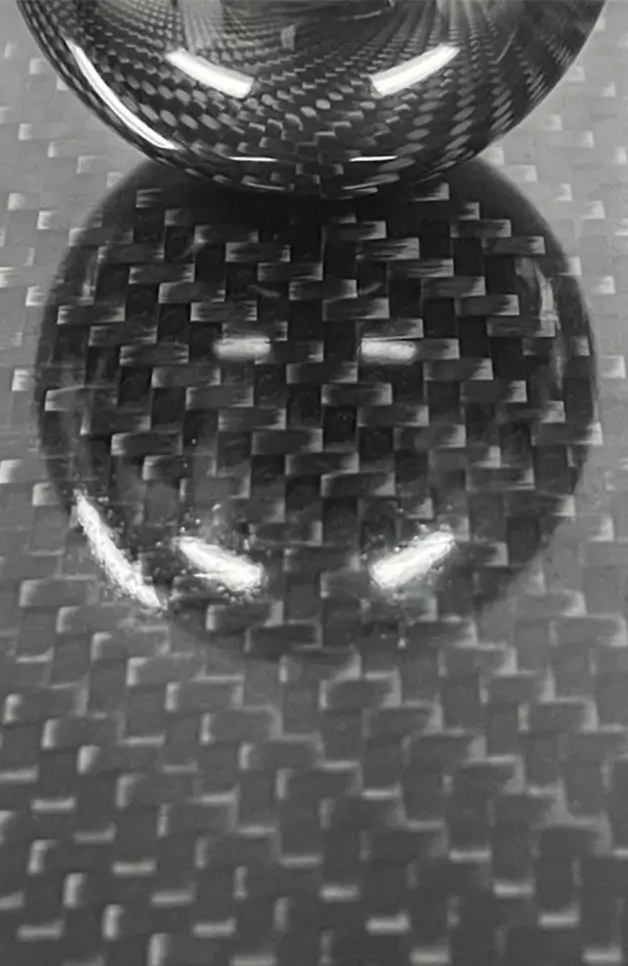

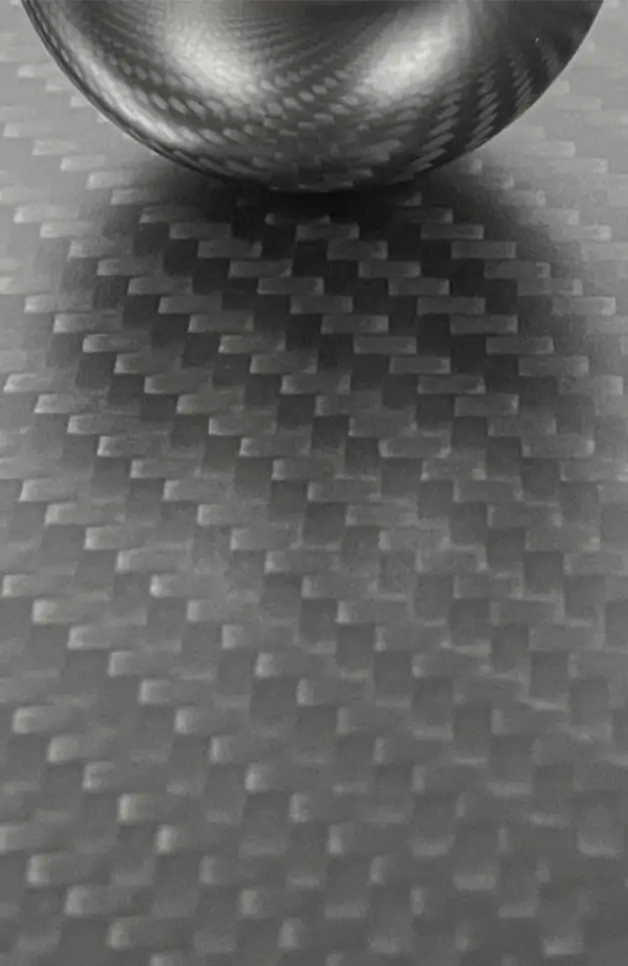

custom carbon fiber appearance

Choose Finishes

Fabrics & Finishes To Meet Your Needs

plain glossy

Modern

twill glossy

Classic

plain matte

Elegant

twill matte

Understated

custom carbon fiber dimensions

Choose

Thicknesses from .01” to 1”

We can accommodate virtually any thickness specification, offering custom sheets in a wide range of thicknesses up to 1”. Alternatively, choose from our seven standard thicknesses, ranging from .010” (0.25mm) to .122” (3.1mm), as shown below.

Our thinnest carbon fiber veneer. Extremely flexible and lightweight, this sheet can be applied over substrates like aluminum or MDF. It wraps around a 1-inch diameter pipe and can be easily cut with scissors or a razor knife. Ideal for creating smooth, flat surfaces.

Our standard thin sheet. This slightly more rigid carbon fiber veneer is perfect for projects with a stiffer panel or substrate. It will wrap around a 4-inch diameter pipe and can be cut with good scissors or a sharp razor knife. The extra thickness helps cover minor imperfections in the underlying substrate.

A medium-thickness sheet. This semi-flexible carbon fiber panel works well as a light structural material or veneer. It can be bent around a 10-12 inch diameter pipe and can be cut with a razor knife (using multiple scoring cuts) or an abrasive cutoff wheel. Edges can be smoothed with 220-grit sandpaper.

A stiffer sheet. This rigid carbon fiber panel is commonly used for light structural applications, like dashboard panels to mount gauges and controls. It can be cut using carbide router/CNC bits or abrasive cutoff wheels. For best results, use continuous rim, non-toothed blades.

A very stiff, semi-rigid structural panel. This carbon fiber sheet offers minimal flex and is perfect for stronger, more rigid applications. It can be cut with carbide bits or abrasive cutoff wheels.

A highly rigid structural panel. This carbon fiber sheet is ideal for lightweight structural components in applications like robotics, UAVs, or quadcopters. Its stiffness makes it an excellent choice for more demanding projects.

A robust, 1/8” thick structural panel. This carbon fiber sheet is designed for heavy-duty structural parts and components that require maximum strength with minimal weight. It can be easily cut with carbide saws or abrasive cutoff wheels. Ideal for demanding applications like knife handles and high-performance components.

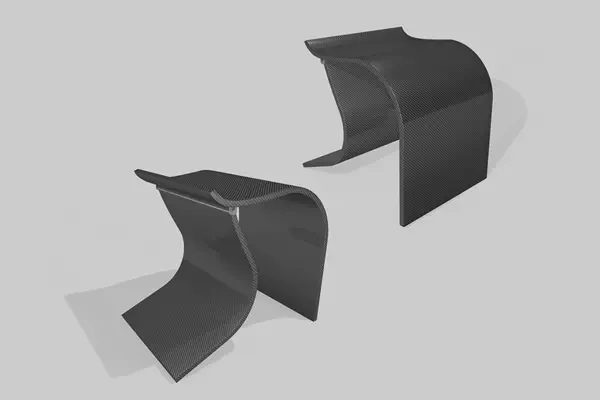

custom carbon fiber case

LangJue Custom SHOW

With advanced technology and expert craftsmanship, we create durable, high-performance custom carbon fiber parts tailored to each project’s needs. From initial prototypes to large-scale production, we ensure top-quality results and help you achieve your manufacturing goals.

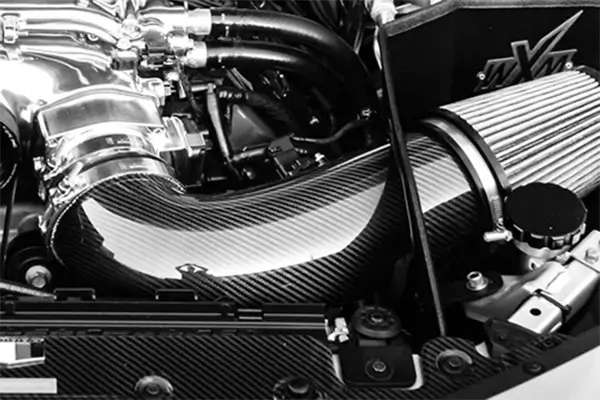

Custom Carbon Fiber Car Parts

Aesthetic & Custom & Durable Performance

Custom Carbon Fiber Motorcycle & Bicycle Parts

Lightweight & High-Strength

Custom Carbon Fiber Sport Parts

Custom Top-Performance Sports Gear

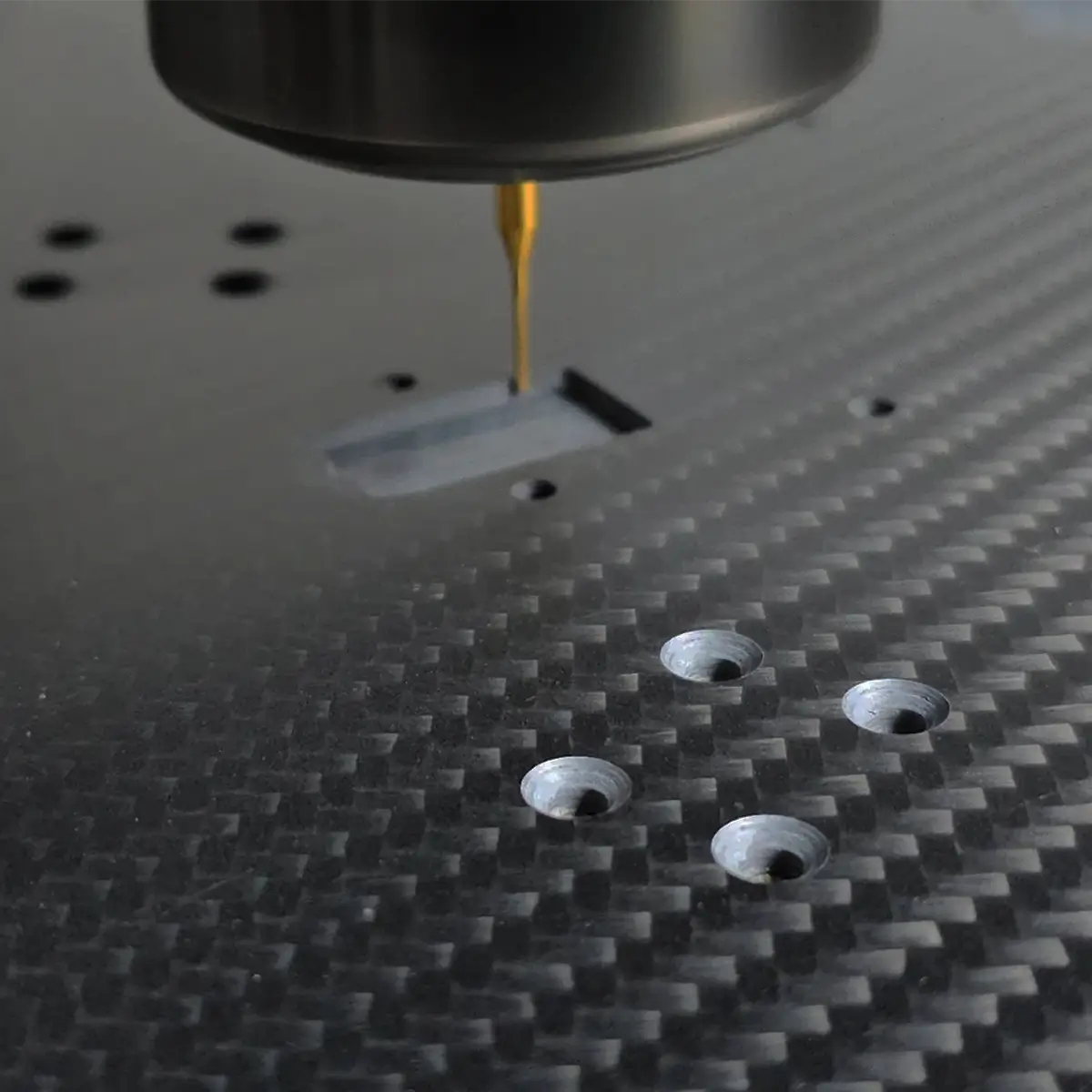

Carbon Fiber CNC Machining

Precision & Complex Machining

OEM Carbon Fiber

Tailored OEM Solutions

Custom Carbon Fiber Tube

Strong & Durable & Versatile Applications

Custom Carbon Fiber Sheet

High-Quality & Durable & Versatile Sheets

Upload Your CAD File

To begin, provide your contact details and upload the CAD file of your design. This allows us to create a detailed 3D model of the part or prototype you're looking to produce.

Receive a Quote & Design Review

Within 12 hours, we’ll send you a detailed quote along with Design for Manufacturability (DFM) feedback. This ensures the feasibility of your project and gives you a clear idea of the costs involved.

Confirm Your Order & Begin Production

Once you approve the quote and design, we’ll proceed with the production of your custom carbon fiber parts.

Shipping & Delivery

Your project enters our manufacturing queue the morning after we receive your approval. On average, custom orders ship within 10-15 business days. In-stock products and samples ship within 48 hours.

Just 4 Steps

Custom Carbon Fiber Parts Quotation Process

From detailed consultation to final delivery, we make custom parts orders simple and easy. We pride ourselves on providing exceptional customer service by anticipating your needs, offering customized solutions and on-time delivery.

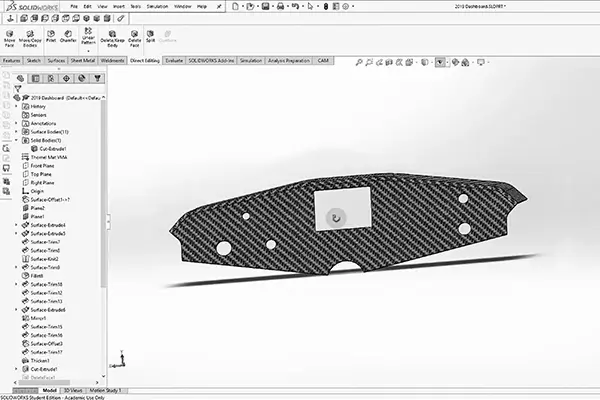

Custom Carbon Fiber CNC Machining

Best in Class Machining Delivers Precision Cuts

Whether you need one part or 1,000, we have the tools and equipment to make precise cuts to the most stringent requirements. With three CNC machines available to accommodate varying needs, our in-house machining team can cut your custom carbon fiber parts to a tolerance of 0.005” to ensure a perfect fit every time.

Professional Equipment For Custom Carbon Fiber

The Equipment Behind Custom Carbon Fiber Parts

From design to production, we meet strict quality standards, addressing complex shapes and performance needs.

Autoclave Moulding

Enhances strength & optimizes durability

Hand Lay-up Process

Meets custom design requirements

Vacuum Diversion

Increases precision & reduces material waste

CNC Machining

High-precision structures

Industrial oven

Even curing & quality stability

From Prototyping To Production

Custom Carbon Fiber Design Process

LangJue custom carbon fiber design process begins with understanding your specific needs. We collaborate closely with you to develop solutions, ensuring the design is optimized for strength, durability, and performance. Through advanced CAD modeling and engineering analysis for high-quality production.

This initial step involves understanding the client’s specific needs and expectations. We collect detailed information on carbon fiber design specifications, functionality, weight, strength, and appearance. Clear communication ensures our team fully grasps the project’s purpose, guiding the design process to achieve desired outcomes.

At this stage, we evaluate technical, economic, and material feasibility. Our engineers assess whether the concept can be realized efficiently while meeting performance goals. We consider factors such as material availability, manufacturing techniques, and cost-effectiveness to confirm the project’s viability.

Our team creates precise 3D models of the product using advanced design software. These models serve as virtual blueprints, enabling detailed visualization of the structure, dimensions, and key features. Accurate modeling lays the groundwork for subsequent analysis and production.

The 3D models are subjected to virtual simulations to test carbon fiber design structural integrity, performance, and durability under various conditions. Stress, thermal, and mechanical analyses help predict product behavior, allowing us to identify potential improvements early.

Using the finalized design, we create a physical prototype to evaluate the real-world application. This prototype serves as a tangible representation, providing valuable insights into the design’s practicality and functionality before mass production.

The prototype undergoes comprehensive testing to ensure it meets all requirements. This includes strength, durability, and performance checks, as well as verifying compliance with industry standards. Any deviations are addressed to confirm the design’s reliability.

Based on feedback from testing, the design is refined to enhance performance, efficiency, or aesthetics. This iterative process ensures the final product achieves optimal results, resolving any shortcomings identified in earlier stages.

With the design finalized, we develop a detailed production plan. This includes defining material requirements, process flows, and quality checkpoints. Proper planning ensures efficient manufacturing, consistent quality, and on-time delivery of the finished product.

Custom Carbon Fiber Production Process

Once the design is finalized, our production process begins. Utilize advanced machines and proven techniques to transform designs into high-performance custom carbon fiber parts. Every step of the process is carefully monitored to ensure the product meets strict quality standards and exceeds your expectations.

This stage involves transforming ideas into tangible carbon fiber design through advanced engineering. Our team evaluates client requirements, creates precise 3D models, and determines optimal structural layouts. Every detail is analyzed to ensure strength, performance, and aesthetic appeal, laying the foundation for a superior product.

High-quality molds are essential for shaping carbon fiber products. We craft molds using precise techniques, ensuring they are smooth, durable, and suitable for repeated use. Proper mold preparation guarantees accurate product dimensions and flawless surfaces.

Only premium-grade carbon fiber materials are selected to ensure top performance. These materials are pre-inspected and prepared to meet the specifications of each project, setting the stage for reliability and durability.

Prepreg sheets (pre-impregnated carbon fiber) are meticulously cut to the required size and shape. Using precision tools, this step ensures minimal waste and uniformity, preparing the materials for perfect alignment during layup.

In this step, layers of carbon fiber are strategically arranged in the mold according to design specifications. Proper layering is critical for achieving desired mechanical properties and structural integrity in the final product.

Under controlled heat and pressure, the layered material is cured and formed into its intended shape. This process bonds the fibers and resin, creating a strong and lightweight component.

After forming, the product is carefully removed from the mold. Special care is taken to prevent any damage or deformation, preserving the precision achieved in earlier steps.

A thorough inspection is conducted to verify the dimensions, structure, and overall quality of the freshly formed blank. This ensures there are no defects before proceeding to the next stage

The product edges are trimmed, and machining is performed to achieve precise shapes and finishes. This process ensures that the component meets exact specifications for its intended application.

Sanding smoothens the product’s surface, preparing it for a flawless paint finish. It removes imperfections and creates an even texture, enhancing the visual and tactile quality.

This step adds protective coatings and a customized appearance. Advanced techniques and durable paints ensure the final product withstands environmental factors while looking polished and professional.

Logos, graphics, or custom designs are applied to the product using high-precision printing techniques. This step enhances branding and adds unique aesthetic appeal.

Components are meticulously assembled into a finished product. Our team ensures seamless integration of parts for optimal functionality, ensuring the final product is ready for use.

A rigorous quality check is performed to detect any defects or inconsistencies. Our strict inspection protocols guarantee that only products meeting our high standards reach the next phase.

Products are securely packaged to protect them during transit. Special care is taken to ensure durability and safety, guaranteeing that customers receive items in perfect condition.

Efficient logistics ensure timely delivery of products to clients. We coordinate transportation details to guarantee smooth shipping and secure handling.

Accurate documentation, including specifications, warranties, and user instructions, is provided with each shipment. This ensures clear communication and supports seamless post-sale processes.

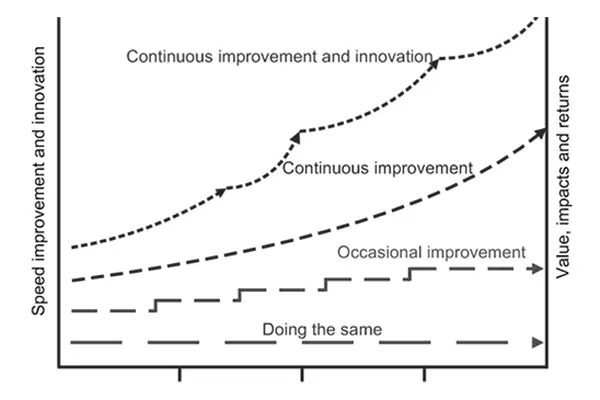

Customer feedback is collected and analyzed to enhance product quality and performance. This step helps us stay aligned with user needs and drives continuous improvement.

Custom Carbon Fiber Quality control Process

Quality is at the core of everything we do. Our comprehensive quality control process includes multiple stages of inspection and testing to guarantee that every custom carbon fiber parts meets the highest industry standards. From material testing to visual inspections, we ensure that each product is durable, precise, and ready to perform in its intended application.

This critical step ensures that all raw materials meet quality standards before production begins. Materials are thoroughly tested for physical and chemical properties, such as strength, weight, and resin content. By verifying the quality of incoming supplies, we ensure consistency and reliability in the finished product.

Maintaining a controlled environment is essential for carbon fiber production. We monitor temperature, humidity, and cleanliness in the production area to prevent contamination and ensure optimal curing. This step guarantees the material properties remain intact throughout manufacturing.

During this stage, each layer of carbon fiber is carefully checked to ensure precise alignment and correct placement within the mold. Proper layup ensures structural integrity and consistent performance, eliminating risks of defects later in the process.

We closely monitor the curing process to ensure the material reaches its intended strength and durability. Heat, pressure, and timing are precisely controlled, with real-time data collection to identify any abnormalities and prevent product inconsistencies.

After the product is removed from the mold, our team inspects the surface for imperfections such as air bubbles, cracks, or uneven textures. A flawless surface is essential for achieving both aesthetic appeal and superior mechanical performance.

Using advanced measurement tools, we verify that the product meets precise dimensional specifications. This ensures compatibility with assembly processes and adherence to customer requirements, guaranteeing a perfect fit for its intended application.

Products are tested under real-world conditions to verify their performance, strength, and functionality. This step includes stress tests, load-bearing assessments, and environmental simulations to confirm the product can withstand its intended use.

Before shipment, the product undergoes a comprehensive quality audit. This final check includes a review of inspection reports, functional performance, and visual standards. Only products that meet our strict quality criteria are approved for delivery to customers.