Custom Carbon Fiber Tube

LJ Professional Customization

Custom Carbon Fiber Tube Catalog

LangJue custom carbon fiber tube parts are carefully crafted using only the finest materials. Our production team offers superior craftsmanship with over 10 years of experience working with custom carbon fiber Intake tube / hood prop tube / sailboat mast tube.

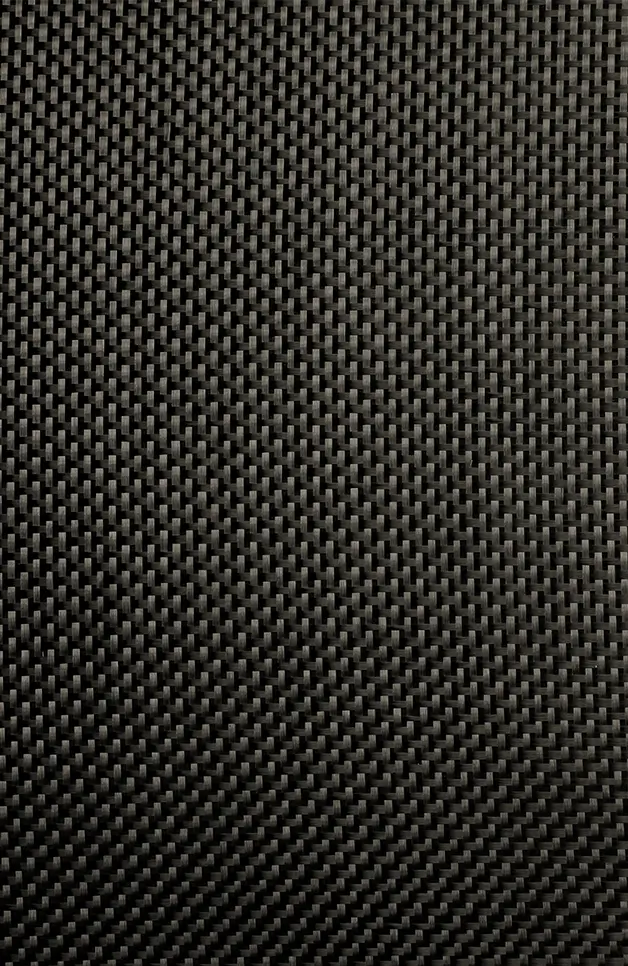

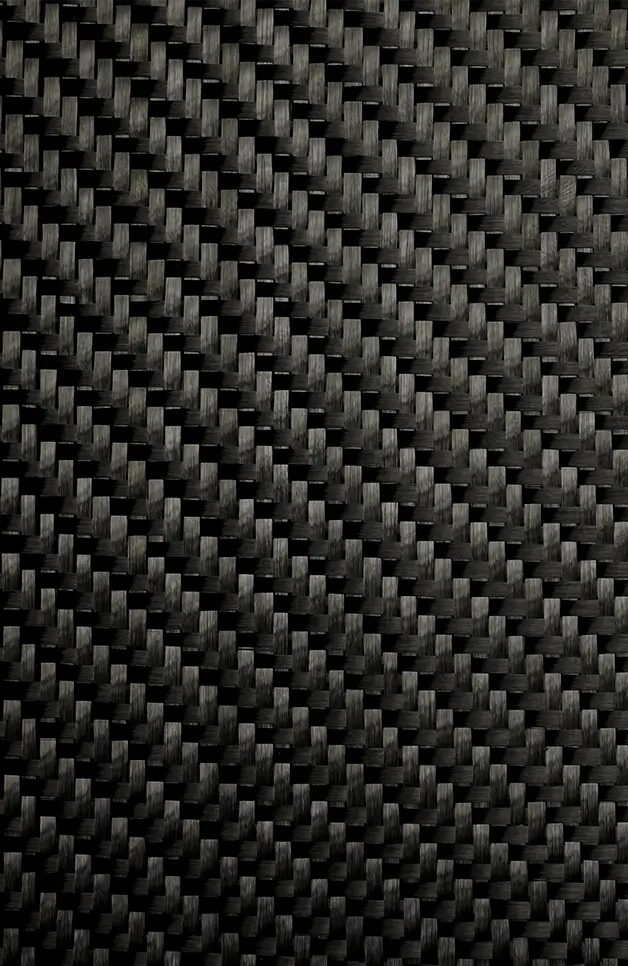

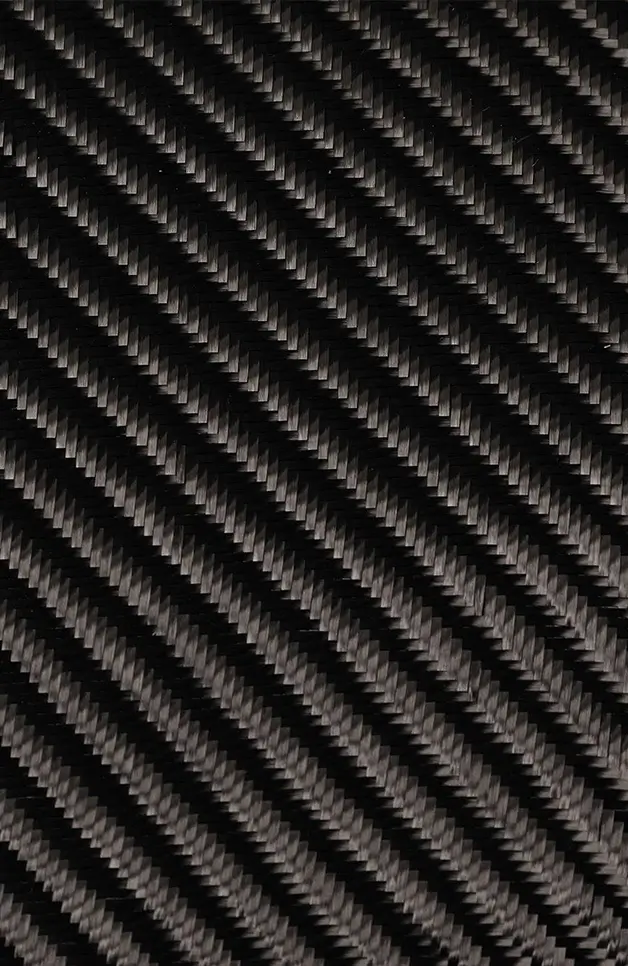

Custom Carbon Fiber Tube Material

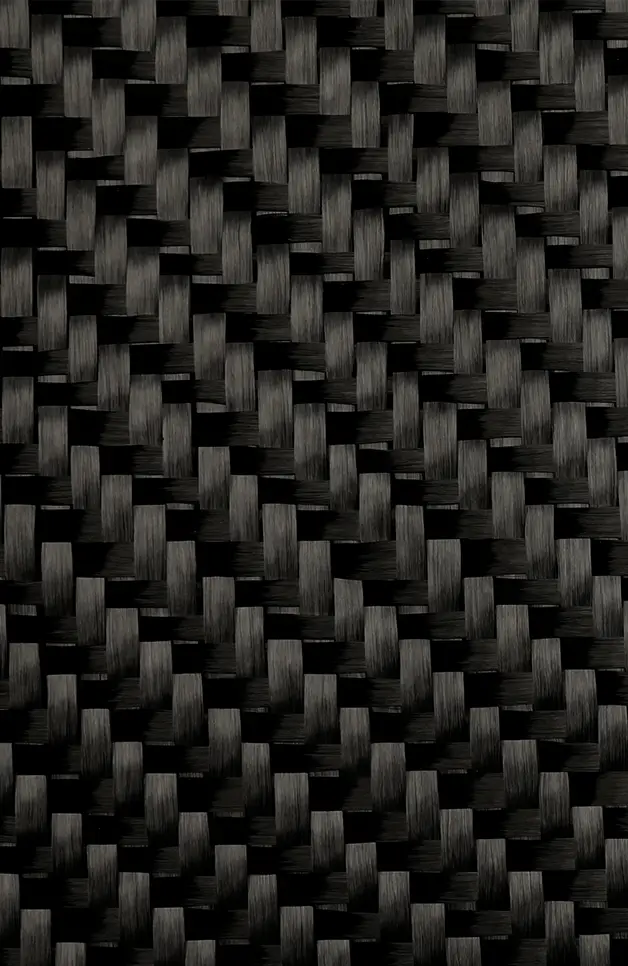

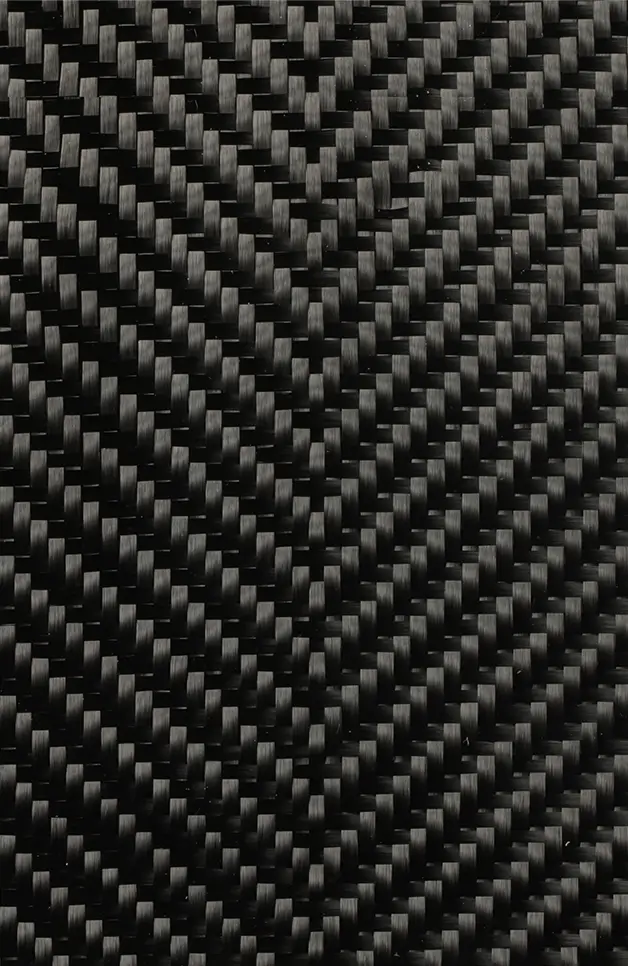

Choose weave and filament count

Select custom carbon fiber tube weave pattern and filament count for optimal strength and performance, with full customization options to meet any specification or requirement

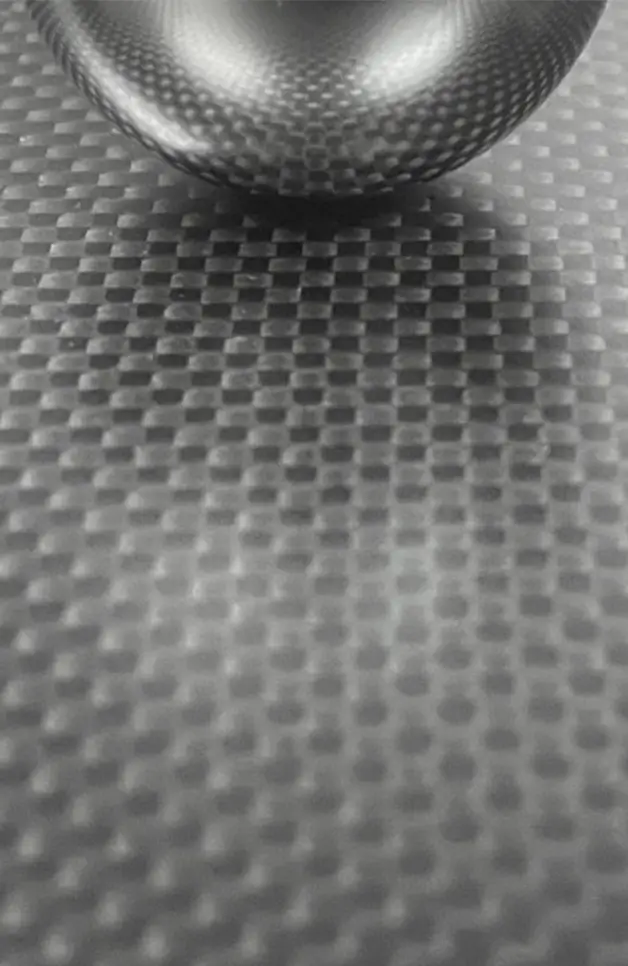

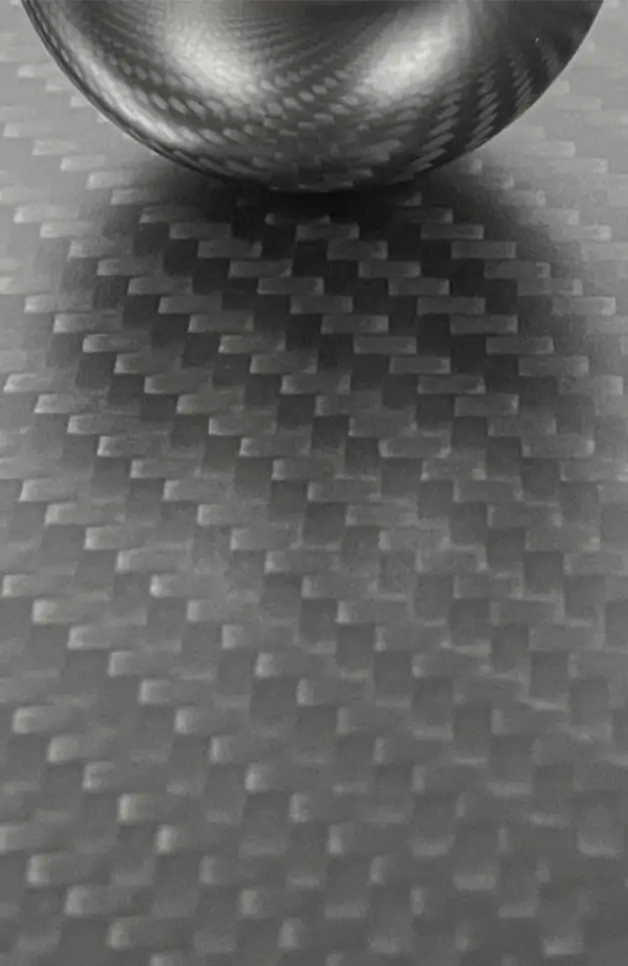

Custom Carbon Fiber Tube appearance

Choose Finishes

Fabrics & Finishes To Meet Your Needs

Plain Glossy

MODERN

Twill Glossy

CLASSIC

Plain Matte

ELEGANT

Twill Matte

UNDERSTATED

Custom Carbon Fiber Tube case

Custom SHOW

With advanced technology and expert craftsmanship, we create durable, high-performance custom carbon fiber tube products tailored to each project’s needs. From initial prototypes to large-scale production, we ensure top-quality results and help you achieve your manufacturing goals.

Upload Your CAD File

To begin, provide your contact details and upload the CAD file of your design. This allows us to create a detailed 3D model of the part or prototype you're looking to produce.

Receive a Quote & Design Review

Within 12 hours, we’ll send you a detailed quote along with Design for Manufacturability (DFM) feedback. This ensures the feasibility of your project and gives you a clear idea of the costs involved.

Confirm Your Order & Begin Production

Once you approve the quote and design, we’ll proceed with the production of your carbon fiber parts.

Shipping & Delivery

Your project enters our manufacturing queue the morning after we receive your approval. On average, custom orders ship within 10-15 business days. In-stock products and samples ship within 48 hours.

Just 4 Steps

Custom Carbon Fiber Tube Quotation Process

From detailed consultation to final delivery, we make custom parts orders simple and easy. We pride ourselves on providing exceptional customer service by anticipating your needs, offering customized solutions and on-time delivery.

Carbon Fiber Customization Process

From Design to Quality Control

Every Step Tailored to Perfection

LangJue carbon fiber customization process ensures precision, quality, and efficiency at every stage. From innovative design and advanced production to rigorous quality control, we transform your ideas into high-performance solutions. Serving diverse industries, we specialize in creating prototypes and full-scale production, turning your vision into reality with unmatched expertise and attention to detail.

Professional Equipment For Carbon Fiber

The Equipment Behind Custom Carbon Fiber Tube

From design to production, we meet strict quality standards, addressing complex shapes and performance needs.

Autoclave Moulding

Enhances strength & optimizes durability

Hand Lay-up Process

Meets custom design requirements

Vacuum Diversion

Increases precision & reduces material waste

CNC Machining

High-precision structures

Industrial oven

Even curing & quality stability

Custom Carbon Fiber Tube FAQs

LangJue specialize in precision parts crafted from high-performance custom carbon fiber, ideal for functional tests or end-use applications. Explore our FAQs to discover more about our carbon fiber solutions and related technical support.

We use 3K resin prepreg bi-directional carbon fiber fabric as usual, we can provide 6K/12K bi-directional carbon fiber fabric as well, and also provide unidirectional carbon fiber fabric.

Plain/twill weave with glossy/matte clear coating. And also we have unidirectional fabric without any weave surface. In additional, we have forged carbon fiber texture weave. You can choose what you want and let us know.

We need 3 details: 1. step/stp/x_t format drawing file; 2. quantity; 3. surface requirement.

Mold time 25-30 days; and sample time 7-10 days;

Yes, we can. But we need samples to scan the dimension or you can provide very detailed dimension to us. We can draft drawing file with surcharge.

Depends on your product drawing file. Most of carbon fiber parts are made by molding, but some simple plate and tubes parts can be made by cnc machined. Our mold is durable metal mold, such as aluminium or steel material.

Aluminium mold, steel mold, fiberglass mold and carbon fiber mold, steel mold with high precision since it is hard and produced by machining, so steel mold is the best option. For inside mold, normally with metal mold, or airbag core or silcone core.

Hot-pressing molding, autoclave molding, vacuum molding, machining and so on…