LangJue CNC machining Service

Custom Precision CNC Parts Shaped for Any Need

Get reliable CNC machining / milling / turning / surface finishe service for your plastic and metal parts, made and delivered when you need them.

Our team is here to help take your product from design and prototyping all the way to full production.

Consistent Processes

Made to order from 1 to 10,000 pieces on demand

Rigorous Quality Control

One-on-one support service Response within 12 hours

Advanced Customization

In-house machine shop, 24/7 operations, Quick turnaround

Timely Delivery

Tight tolerance ±0.05mm Surface roughness Ra0.2μm

What we can offer

CNC Machining Service

Fast - Reliable - Cost Effective

Are you searching for a trusted partner to deliver high-quality CNC machining service with quick turnaround times? At Langjue, we specialize in providing top-tier CNC machining solutions in China, offering both prototyping and precision machining for final-use components.

Our extensive range of CNC machining services includes milling, turning, drilling, tapping, EDM (Electrical Discharge Machining), and wire EDM, accommodating various materials. With our ISO 9001-certified processes and state-of-the-art CNC equipment, we ensure that your parts are manufactured to perfection, right from the start.

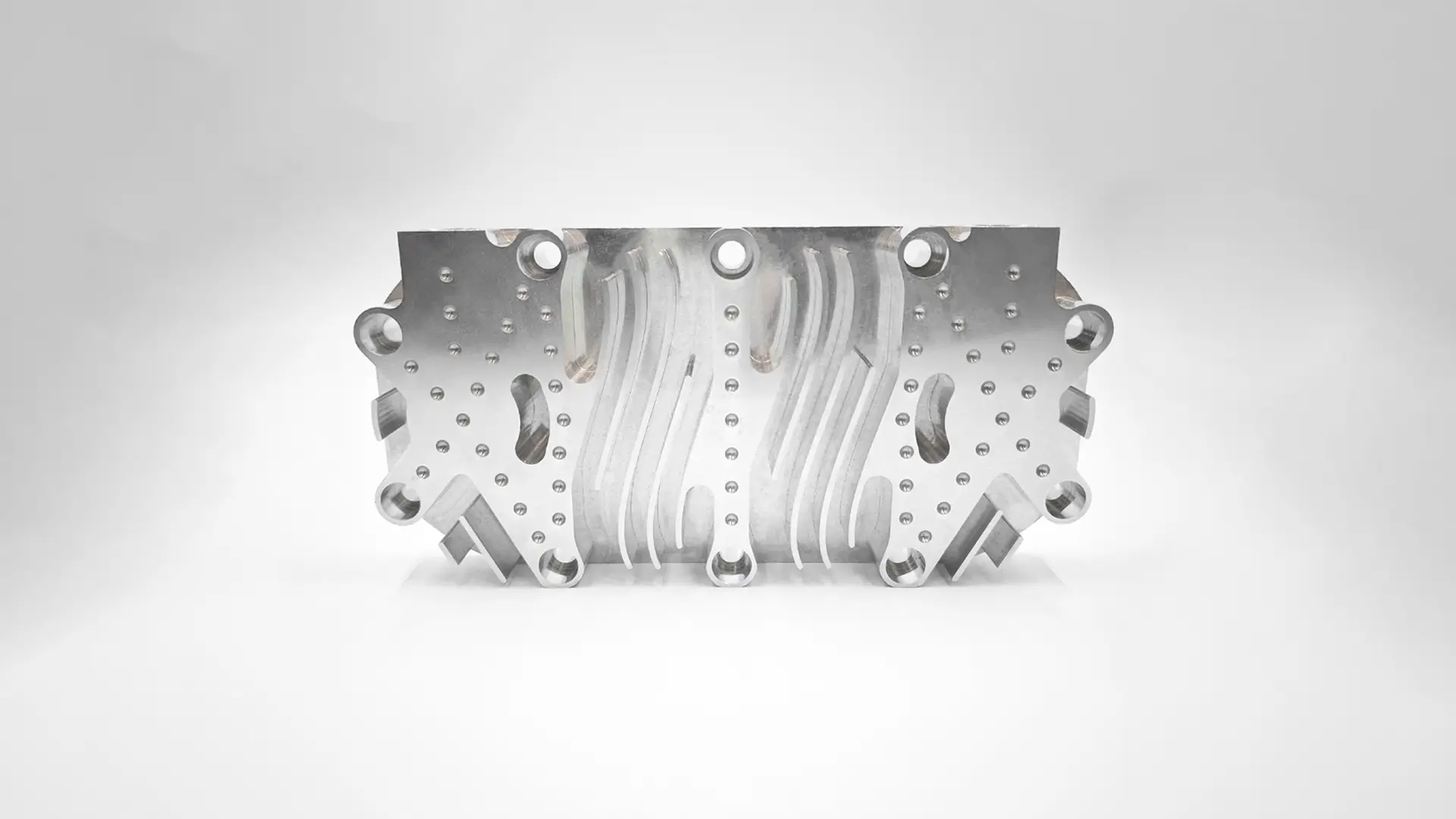

CNC MACHINING SERVICE

CNC milling is a precision manufacturing process that removes material using a rotating cutting tool. This method is ideal for cutting and shaping various plastic and metal materials. CNC milling is versatile, catering to industries requiring accurate components and serving as a highly effective solution for creating molds.

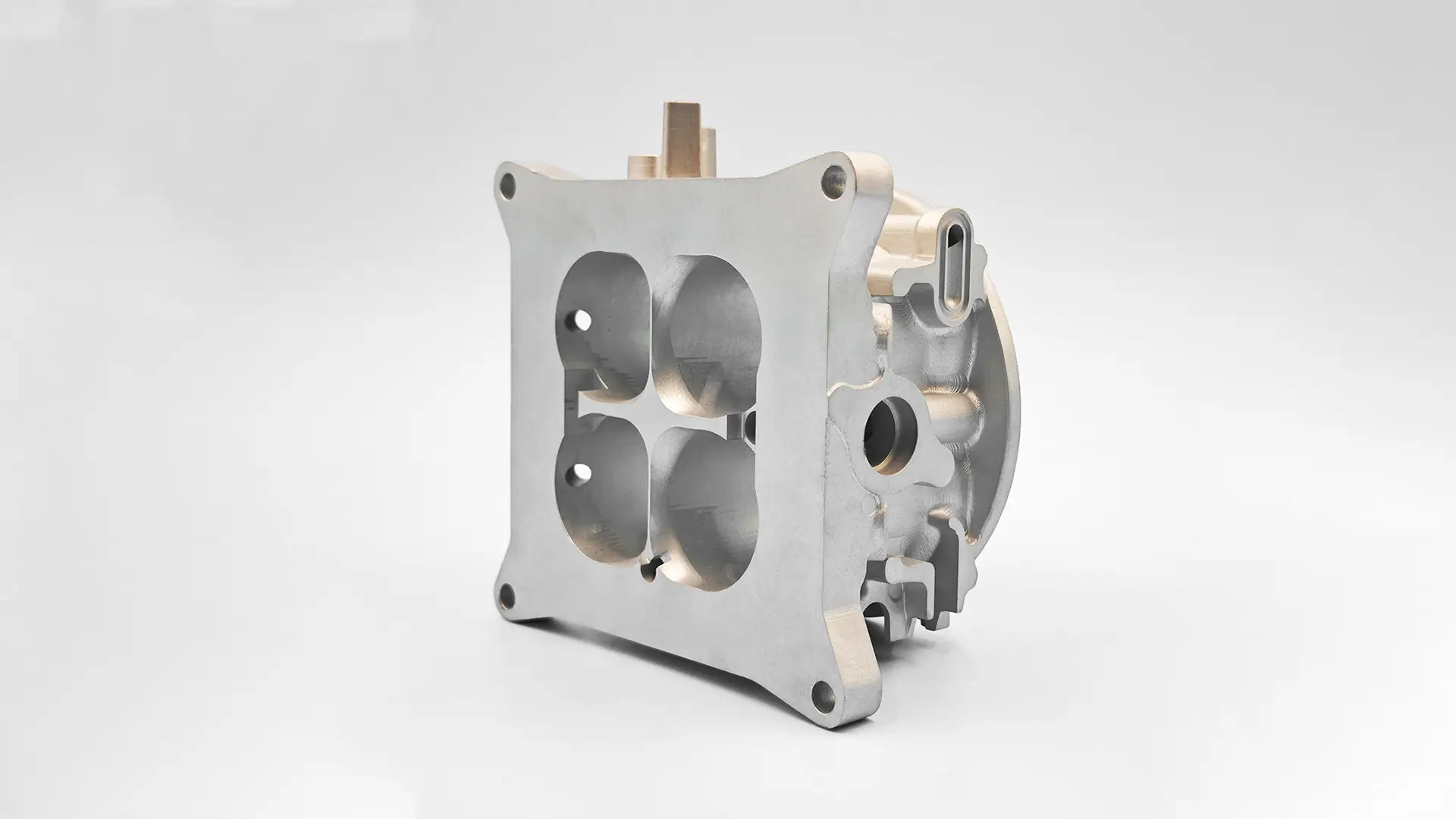

CNC MACHINING SERVICE

CNC turning involves the removal of material by bringing a cutting tool into contact with a high-speed, rotating workpiece. CNC turning enables the creation of intricate external shapes and internal features, including threading and hole machining, delivering exceptional versatility for complex designs.

CNC Machining Tolerances

According to IS0 2768-1:1989, Values in millimeters.

| Basic size range | Fine | Medium | Coarse | Very coarse |

|---|---|---|---|---|

| 0.5 up to 3 | ± 0.05 | ± 0.1 | ± 0.2 | - |

| over 3 up to 6 | ± 0.05 | ± 0.1 | ± 0.3 | ± 0.5 |

| over 6 up to 30 | ± 0.1 | ± 0.2 | ± 0.5 | ± 1 |

| over 30 up to 120 | ± 0.15 | ± 0.3 | ± 0.8 | ± 1.5 |

| over 120 up to 400 | ± 0.2 | ± 0.5 | ± 1.2 | ± 2.5 |

| over 400 up to 1000 | ± 0.3 | ± 0.8 | ± 2 | ± 4 |

| over 1000 up to 2000 | ± 0.5 | ± 1.2 | ± 3 | ± 6 |

| over 2000 up to 4000 | - | ± 2 | ± 4 | ± 8 |

LJ Professional Customization

At Langjue, we adhere to standard tolerances based on ISO 2768, with medium tolerances for machined plastics and fine tolerances for machined metals. Typically, our CNC machining can achieve tolerances ranging from ±0.005″ (±0.125mm) to ±0.002″ (±0.05mm). For projects requiring tighter tolerances, a detailed 2D drawing with full specifications will be required. Our experienced engineering team will work closely with you to ensure critical dimensional requirements are met and deliver the highest possible precision for your parts.

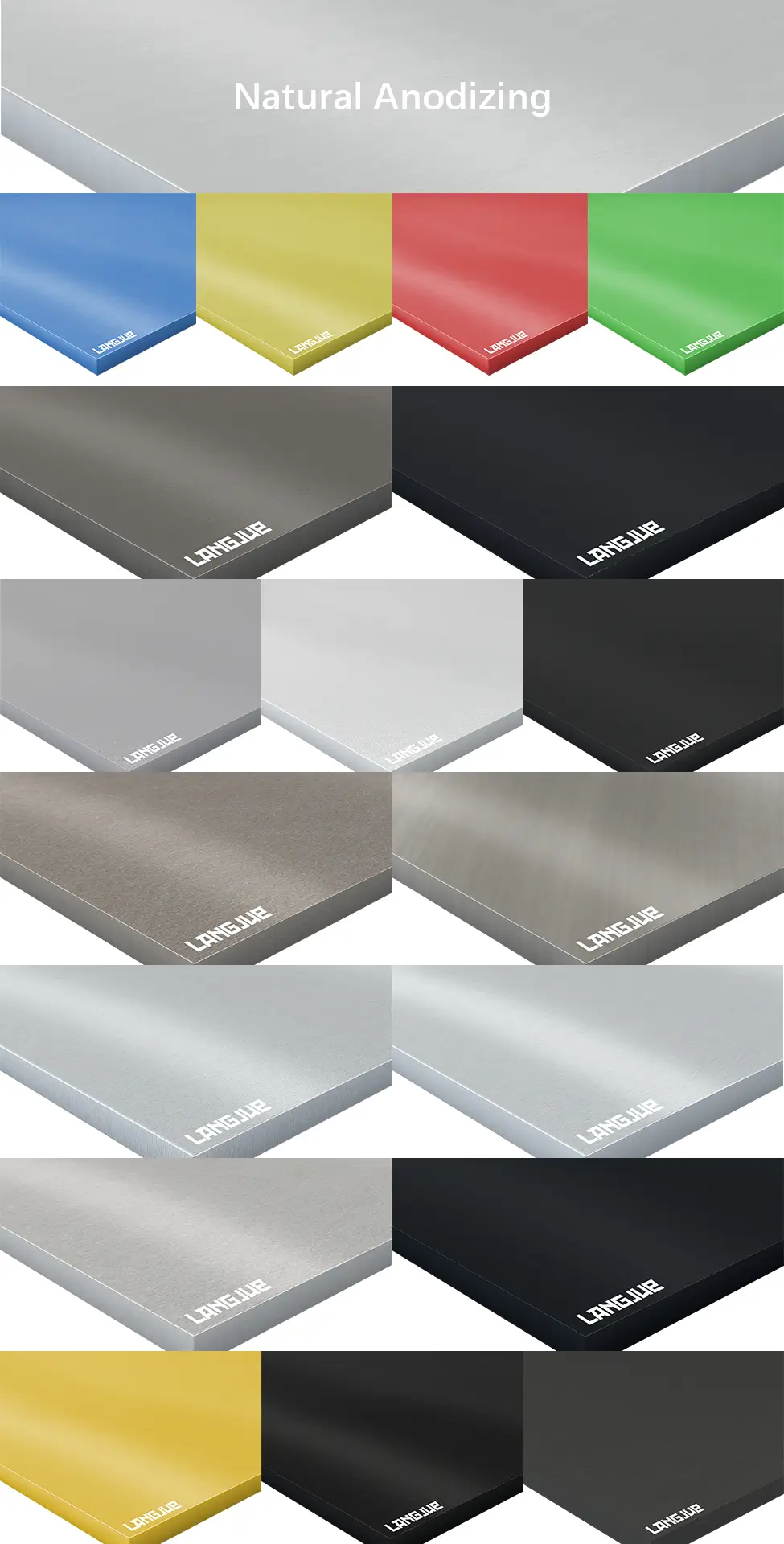

CNC Machining Surface Finishes

We offer complete CNC machining surface finishing solutions designed to meet both aesthetic and functional needs for any project. Our services include a variety of finishes such as sanding, sandblasting, mirror polishing, painting, printing, laser engraving, anodizing, electroplating, nickel plating, chrome plating, powder coating, and more. Each finish is tailored to enhance the performance and appearance of your components.

CNC Machining Materials

A16061, A16063, A16082, A17075, Al2024, A15052, A380, etc.

55201, 55301, 55303, SS304, 55316, 55416, etc.

Mild Steel, Carbon Steel, 4140, 4340, Q235, Q34513, 20#, 45#, etc.

C35600, C36000, C37700, C37000, C37100, C28000, C26000, C24000, C22000, etc.

C11000, C12000, C12200, C10100, etc.

20#, 45#, Q235, Q345, Q3458, 1214, 12L14, 1215, etc.

POM, Peek, PMMA, ABS, Del Rin, Nylon, PVC, PP, PC, etc.

CNC machining application

CNC Machining SHOW

LangJue have collaborated with manufacturers across numerous industries, ranging from consumer products to large-scale industrial applications. Transforming your vision into reality—from initial prototypes to full-scale production.

Upload Your CAD File

To begin, provide your contact details and upload the CAD file of your design. This allows us to create a detailed 3D model of the part or prototype you're looking to produce.

Receive a Quote & Design Review

Within 12 hours, we’ll send you a detailed quote along with Design for Manufacturability (DFM) feedback. This ensures the feasibility of your project and gives you a clear idea of the costs involved.

Confirm Your Order & Begin Production

Once you approve the quote and design, we’ll proceed with the production of your CNC prototype or machined parts.

Shipping & Delivery

Your CNC machined parts will be completed within a few days and shipped via international express. We encourage you to share feedback to ensure your order meets your expectations.

Just 4 Steps

The CNC Machining Quotation Process

From detailed consultation to final delivery, we make custom parts orders simple and easy. We pride ourselves on providing exceptional customer service by anticipating your needs, offering customized solutions and on-time delivery.

To offer an accurate and detailed quote, we require the following details:

1.CAD files in 2D or 3D formats, including STP, IGES, X_T, DWG, PDF, or STL.

2.The desired quantities, machining processes, and the type of raw materials.

3.Any secondary operations required, such as finishing, heat treatments, anodizing, or plating.

4.Specific customer requirements, including First Article Inspection (FAI), PPAP, or external certification needs.

5.Additional helpful information, like target pricing or expected lead times.

As a contract manufacturer, we don’t typically handle part design, but we can assist with Design for Manufacturability (DFM). Through DFM guidance, we help optimize your design for efficiency and cost reduction while maintaining its intended functionality.

We strive to respond to quote requests within one business day. To expedite the process, please provide complete and accurate project information, which helps us deliver faster and more precise feedback.

Our lead times vary depending on our current workload, the part’s complexity, and the order size. After your purchase order is confirmed, documentation completed, and materials secured, we’ll provide an exact delivery timeframe. This can range from as little as three business days to several weeks.

For international orders, quality assurance is key, and our ISO-9001-certified facility ensures consistent, reliable results. Equipped with advanced inspection tools and a skilled QC/QA team, we deliver:

1.2D inspection reports, CMM reports, or 3D scanning reports.

2.Full documentation of all dimensional tolerances, geometric tolerances, and specifications.

3.Statistical sampling based on MIL-STD-105E standards, guaranteeing zero defects.

All inspection reports are packaged and sent along with your completed parts for transparency and peace of mind.

CNC Machining Quotes FAQs

We provide precision parts made from engineering-grade materials, perfect for functional tests or final use. Explore our FAQs to learn more about CNC machining services and related technical support.

CNC Machining FAQs

We provide precision parts made from engineering-grade materials, perfect for functional tests or final use. Explore our FAQs to learn more about CNC machining services and related technical support.

CNC machining, or computer numerical control machining, encompasses a variety of processes we specialize in, such as: Precision milling, Turning, Drilling, Threading and tapping, EDM and wire EDM, Custom surface finishing, Prototype manufacturing, Small-batch and one-off runs, Modifying existing parts, Assistance with material sourcing, Limited warehousing and organized part dispatching, We handle projects from prototypes to full-scale production, delivering anywhere from 1 to 10,000 pieces. Quick turnarounds are a priority, with deliveries available in as few as three days.

Our dedicated engineering and sales teams provide tailored quotes based on your project needs. For similar components, CNC lathe machining typically costs 15% less than standard 3-axis milling. However, continuous 5-axis milling is approximately 20% more expensive than indexed 5-axis (or 3+2 milling) and can cost twice as much as 3-axis milling. For cost efficiency, consider larger production runs to offset setup expenses.

3-Axis Milling: Maximum dimensions of 1270×508×635 mm

5-Axis Milling: Maximum dimensions of 450×700×400 mm, with a worktable diameter of Φ400 mm

The standard finish, known as “as-machined” or “as-milled,” displays minimal tool marks. Surface roughness (Ra) typically falls between 1.6-3.2 μm. Enhanced finishes, ranging from 0.8-1.6 μm to 0.2-0.8 μm, are available for projects requiring a finer texture, though additional costs and machining time may apply.